Mechanical

American Tube and Pipe manufactures galvanized mechanical tubing in round, square, and rectangle shapes to meet our customers’ highest specifications.

American Tube and Pipe manufactures galvanized mechanical tubing in round, square, and rectangle shapes to meet our customers’ highest specifications.

American Tube and Pipe produces a full range of galvanized mechanical tubing in round, square, and rectangle shapes. Our testing and inspection procedures ensure high quality physical properties, weld integrity, coating quality, dimensional specifications, as well as length, twist, and straightness tolerances. It is easy to fabricate, powder coat and weld, and we offer custom lengths to fit your specific needs.

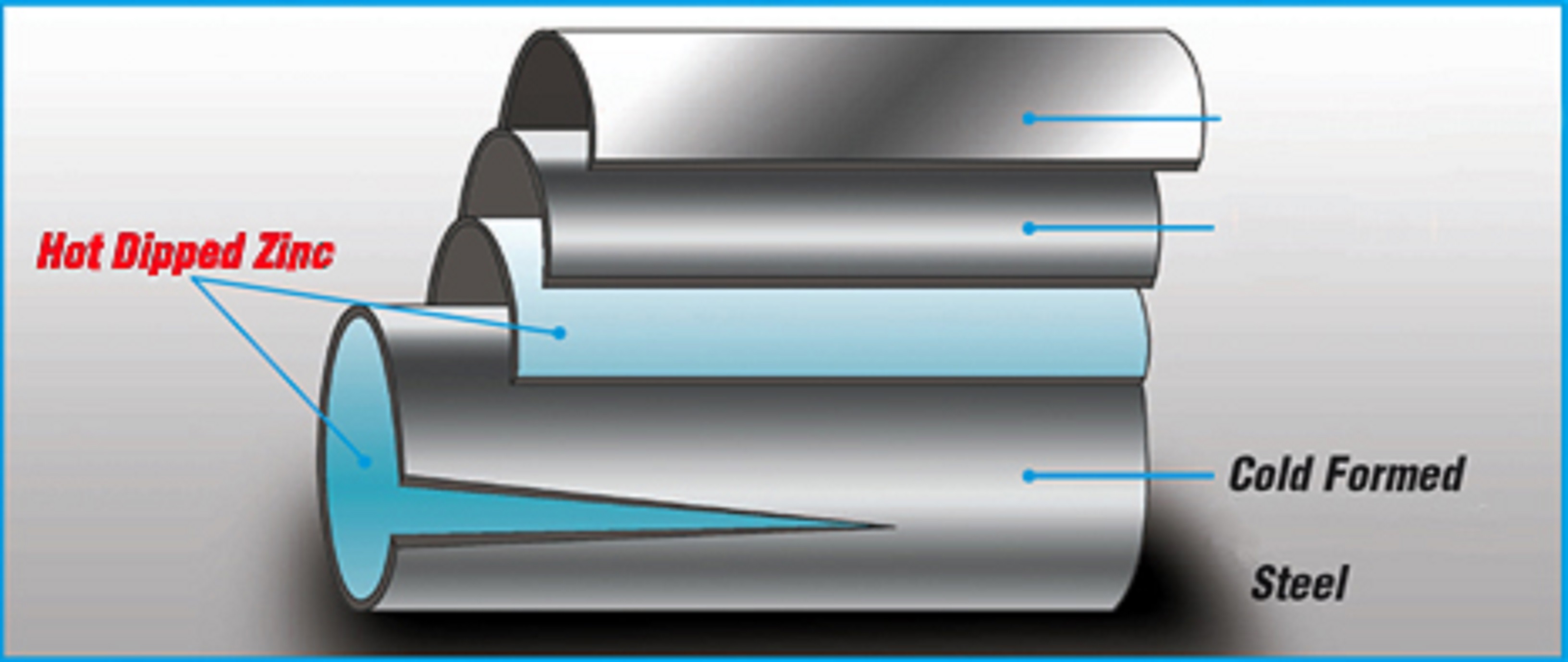

Our mechanical tubing is typically made from high strength steel sheet with 50,000 minimum yield and 55,000 minimum tensile conforming to A653/A653M ASTM standards. The sheet is hot dipped galvanized(OD and ID) at the mill under state-of-the-art coating and temperature controls, ensuring the highest level of adhesion and uniformity. This superior method of galvanizing eliminates flaking and spot rusting. The zinc used is of the highest quality conforming to ASTM B-6.

Exceptionally durable, our tube will meet your toughest design challenges. Because it is produced from high strength steel, the strength properties can be met with thinner steel walls. This reduces weight, and makes your fabrication process easier.

Specs:

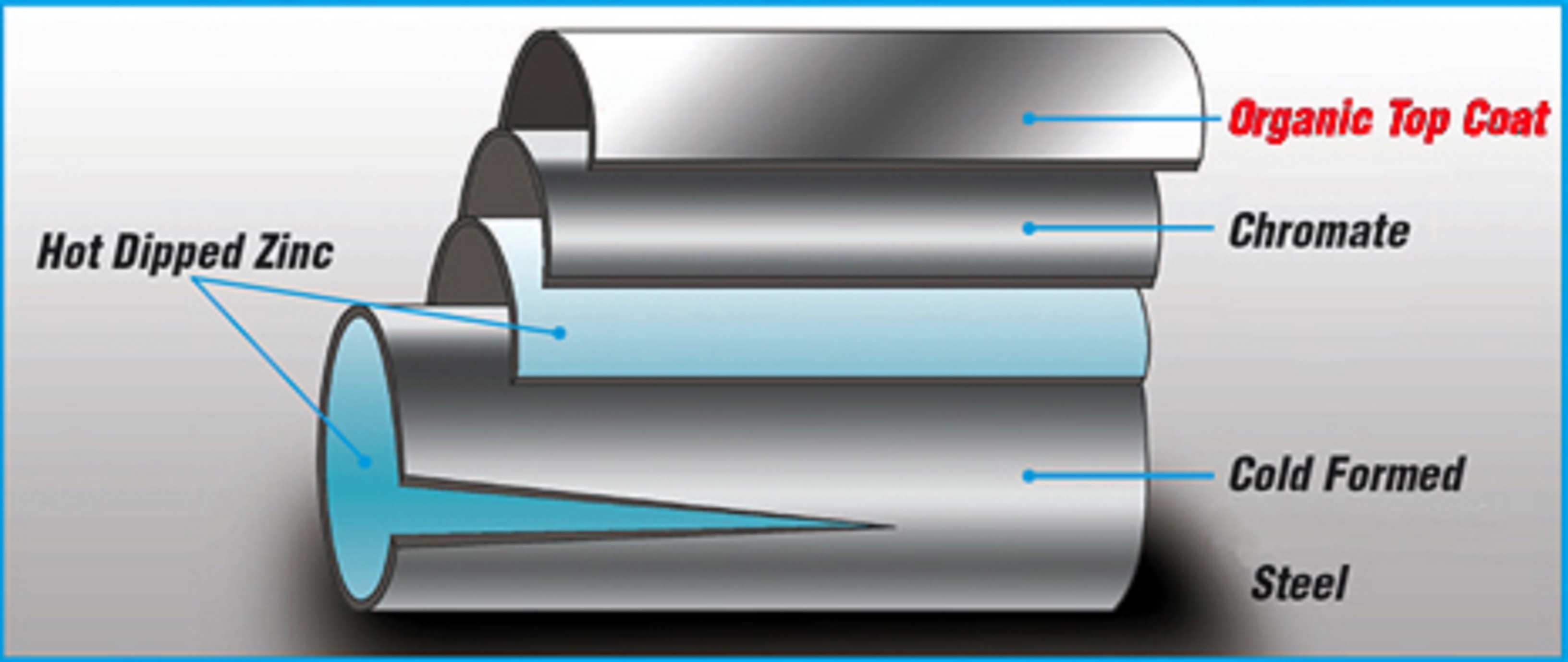

Download Mechanical Capabilities PDFGalvanized with zinc on the inside and outside of the tube is only the first step in our coating process. We then apply a chromate conversion coating to inhibit white rust and enhance already strong corrosion resistance. The last step is a clear organic topcoat which seals in the protection and produces a luminous protective finish. The topcoat also makes a great primer for any paint or powder coat and is fabrication friendly.

In fact, our coating process is so effective it is hard to believe. Independent testing agencies have salt spray tested (ASTM B117) our G90 product for 4000 hours with no sign of red rust and our G185 product for 7000 hours with no sign of red rust. Many of our competitors advertise 1000 hours to 5% red rust on the exterior!

Even more shocking is our interior salt spray test results. Many of our competitors (especially those who utilize inline-galvanizing) will only certify interior salt spray tests of 650 hours with 5% red rust. Independent testing agencies have tested the interior of our G90 product, and we have consistently achieved results between 2000 and 3000 hours before 5% red rust was observed. If your end user is putting the pipe outside, interior corrosion protection matters!

Applications

Please fill out the form below and we will respond promptly.